West Coast Reduction RotaDisc Dryer Replacement

Vancouver, British Columbia

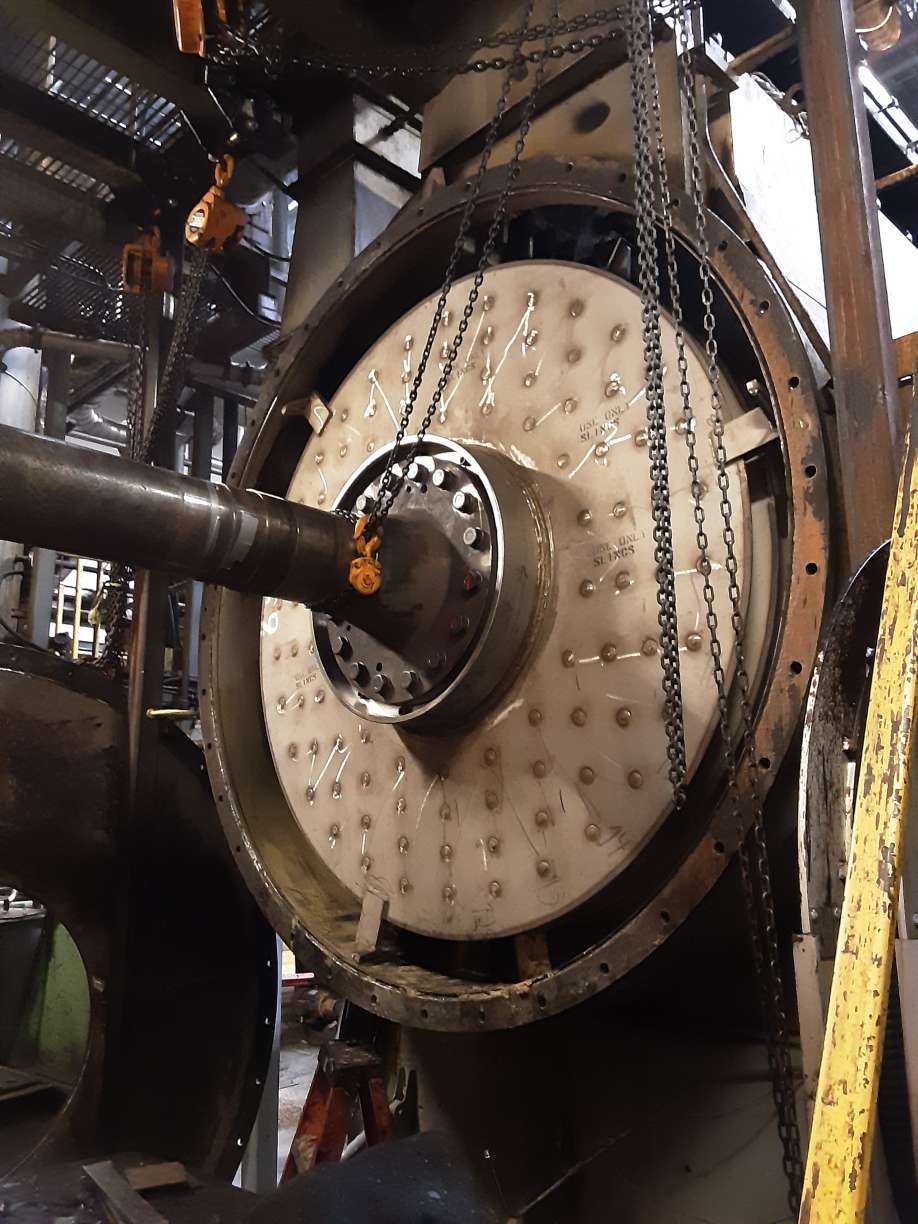

Replacement of a 50-ton RotaDisc dryer and associated work. The RotaDisc dryer is used to recycle food waste and-products from food producers, like farms, restaurants and supermarkets, transforming them into ingredients used in renewable energy, animal feed, soap and more. Work was conducted over a period of 24 days.

Scope Items

- Site mobilization and safety course/orientation.

- Rotor end bearing/saddle support removals.

- 6×6 wood sliders installation and strapping.

- Strip excess assemblies and place slider guide.

- Install temporary floor angle braces (Peri-form jacks).

- Jack rotor out of shell to temporary wall.

- Arrange wood wall removal and crane schedule.

- Sunday crane logistics and rotor removal.

- Prepare new rotor with bearings and saddles torqued.

- Clean old housing and align for new rotor installation.

- Arrange wood wall removal and second crane schedule.

- Sunday crane logistics installing new rotor into shell.

- Reinstate wood temporary wall after new rotor install.

- Slide rotor into internal bearings and finalize alignment.

- Finish bolt up on housings and end plates.

- Test rotate new rotor and test run all assemblies.

- Final commissioning of rotor assembly and reconnections.

Additional Scope Items

- Cut all the bolts around the end cover plate to allow for removal of the cover plate.

- Cut 80% of the flights off for easier removal of the old Rotadisc drum.

- Fabricated and welded L tabs to attach the timbers to.

- Wire wheel and cleaned off the face of the end plate for a batter seal.

- Welded imperfections on the cover plate and ground flat.

- Wire wheeled pillow block flange and half rings, cleaned and wire wheeled contact locations.

- Cut bearings off and retrieved needed components.

- Fabricated locations in order to be able to place jacks.

- Wire brushed and cleaned all hardware needed.

- Fabricated dogs in order to push out dryer bushing.

- Cleaned and wire wheeled pillow block mounting locations.

- Grinded with sand-paper discs the inside of the dryer, for easier installation of the new drum.

- Tapped and chased all holes for the new stub shaft.

- Torqued all bolts to specification.

- Cleaned and wire wheeled all stub shafts for better seating and sealing.

- Wire wheeled all new bearing components and support rings due to excessive corrosion.

- Moved cover plate out of the way to allow installation of the new drum.

- Washed the inside of the dryer with degreaser.

- Fabricated more slides for new drum install.

- Fabricated lifting eyes and welded into key locations for lifting points.

West Coast Reduction RotaDisc Dryer Replacement

Vancouver, British Columbia

Replacement of a 50-ton RotaDisc dryer and associated work. The RotaDisc dryer is used to recycle food waste and-products from food producers, like farms, restaurants and supermarkets, transforming them into ingredients used in renewable energy, animal feed, soap and more. Work was conducted over a period of 24 days.

Scope Items

- Site mobilization and safety course/orientation.

- Rotor end bearing/saddle support removals.

- 6×6 wood sliders installation and strapping.

- Strip excess assemblies and place slider guide.

- Install temporary floor angle braces (Peri-form jacks).

- Jack rotor out of shell to temporary wall.

- Arrange wood wall removal and crane schedule.

- Sunday crane logistics and rotor removal.

- Prepare new rotor with bearings and saddles torqued.

- Clean old housing and align for new rotor installation.

- Arrange wood wall removal and second crane schedule.

- Sunday crane logistics installing new rotor into shell.

- Reinstate wood temporary wall after new rotor install.

- Slide rotor into internal bearings and finalize alignment.

- Finish bolt up on housings and end plates.

- Test rotate new rotor and test run all assemblies.

- Final commissioning of rotor assembly and reconnections.

Additional Scope Items

- Cut all the bolts around the end cover plate to allow for removal of the cover plate.

- Cut 80% of the flights off for easier removal of the old Rotadisc drum.

- Fabricated and welded L tabs to attach the timbers to.

- Wire wheel and cleaned off the face of the end plate for a batter seal.

- Welded imperfections on the cover plate and ground flat.

- Wire wheeled pillow block flange and half rings, cleaned and wire wheeled contact locations.

- Cut bearings off and retrieved needed components.

- Fabricated locations in order to be able to place jacks.

- Wire brushed and cleaned all hardware needed.

- Fabricated dogs in order to push out dryer bushing.

- Cleaned and wire wheeled pillow block mounting locations.

- Grinded with sand-paper discs the inside of the dryer, for easier installation of the new drum.

- Tapped and chased all holes for the new stub shaft.

- Torqued all bolts to specification.

- Cleaned and wire wheeled all stub shafts for better seating and sealing.

- Wire wheeled all new bearing components and support rings due to excessive corrosion.

- Moved cover plate out of the way to allow installation of the new drum.

- Washed the inside of the dryer with degreaser.

- Fabricated more slides for new drum install.

- Fabricated lifting eyes and welded into key locations for lifting points.