Hammersley Dyke Fish-Friendly Water Pump Station

Agassiz, British Columbia

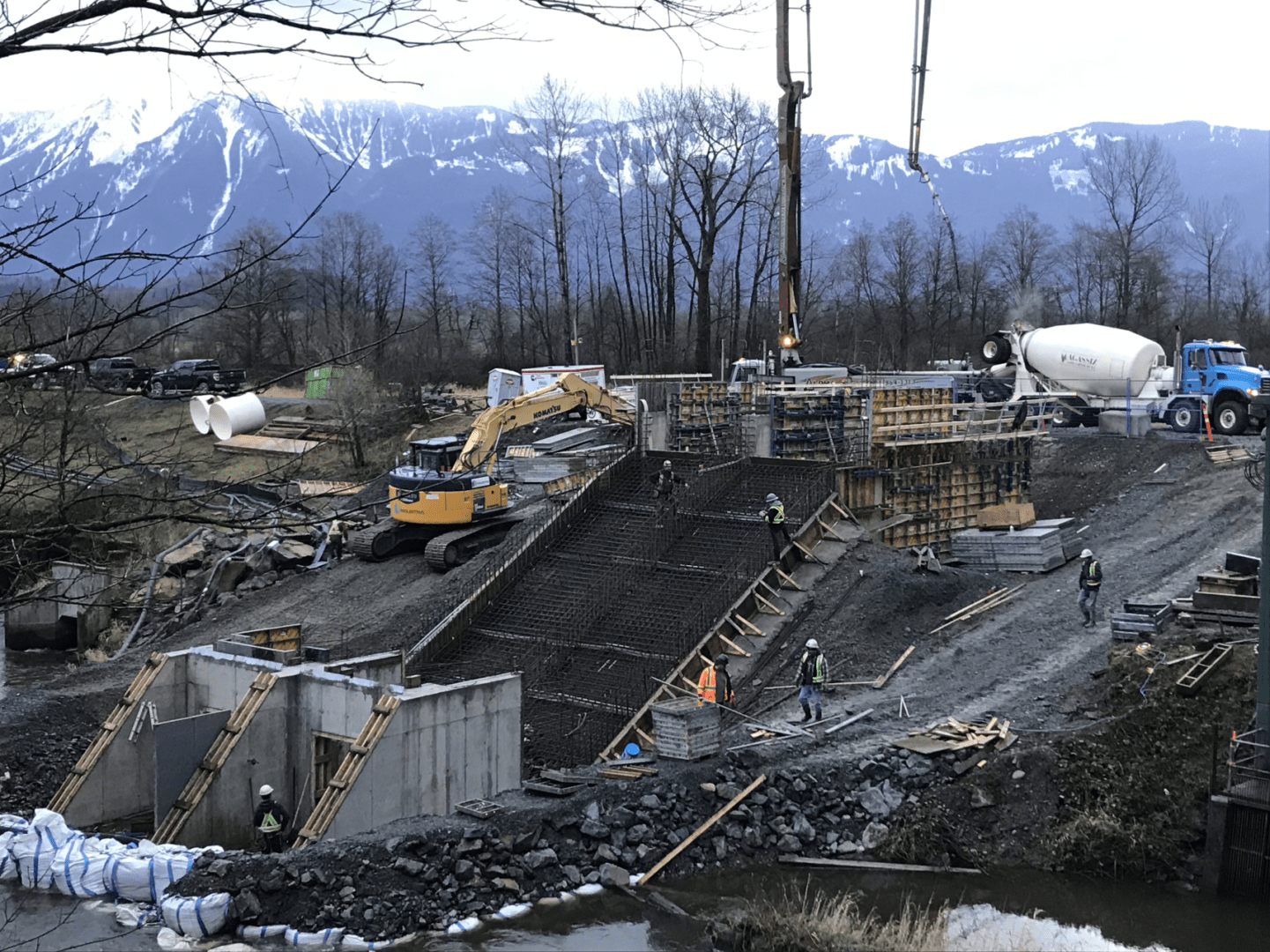

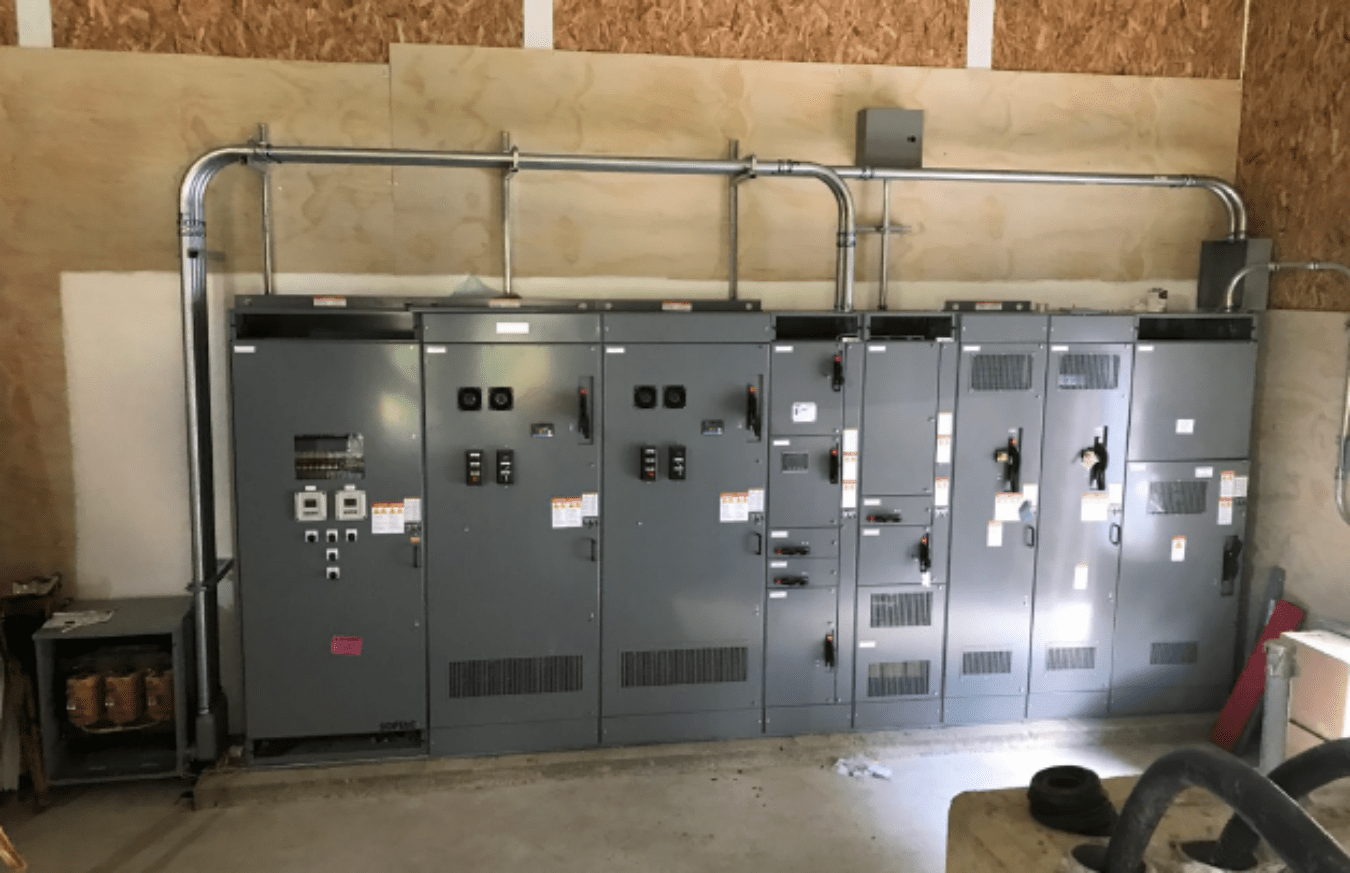

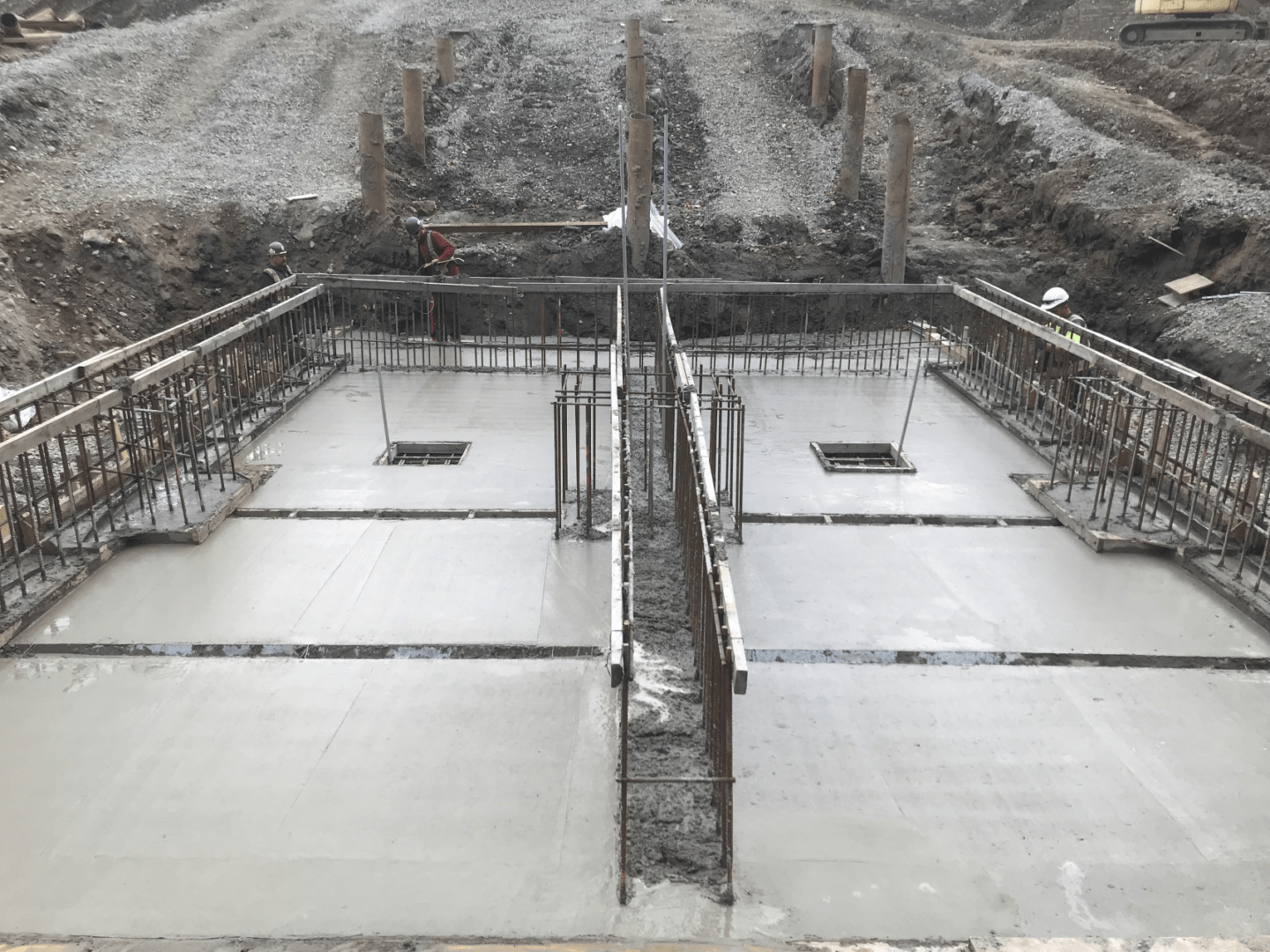

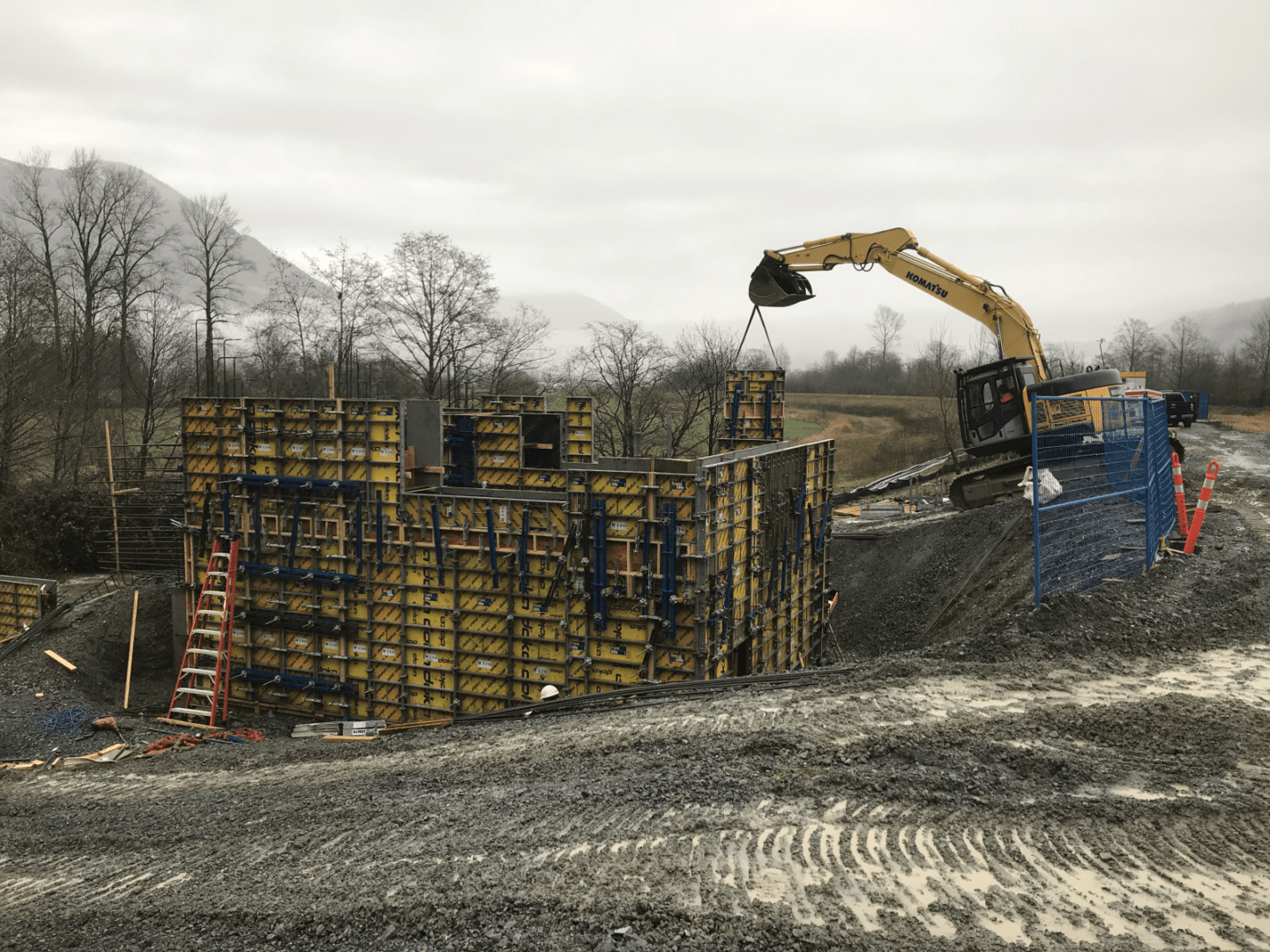

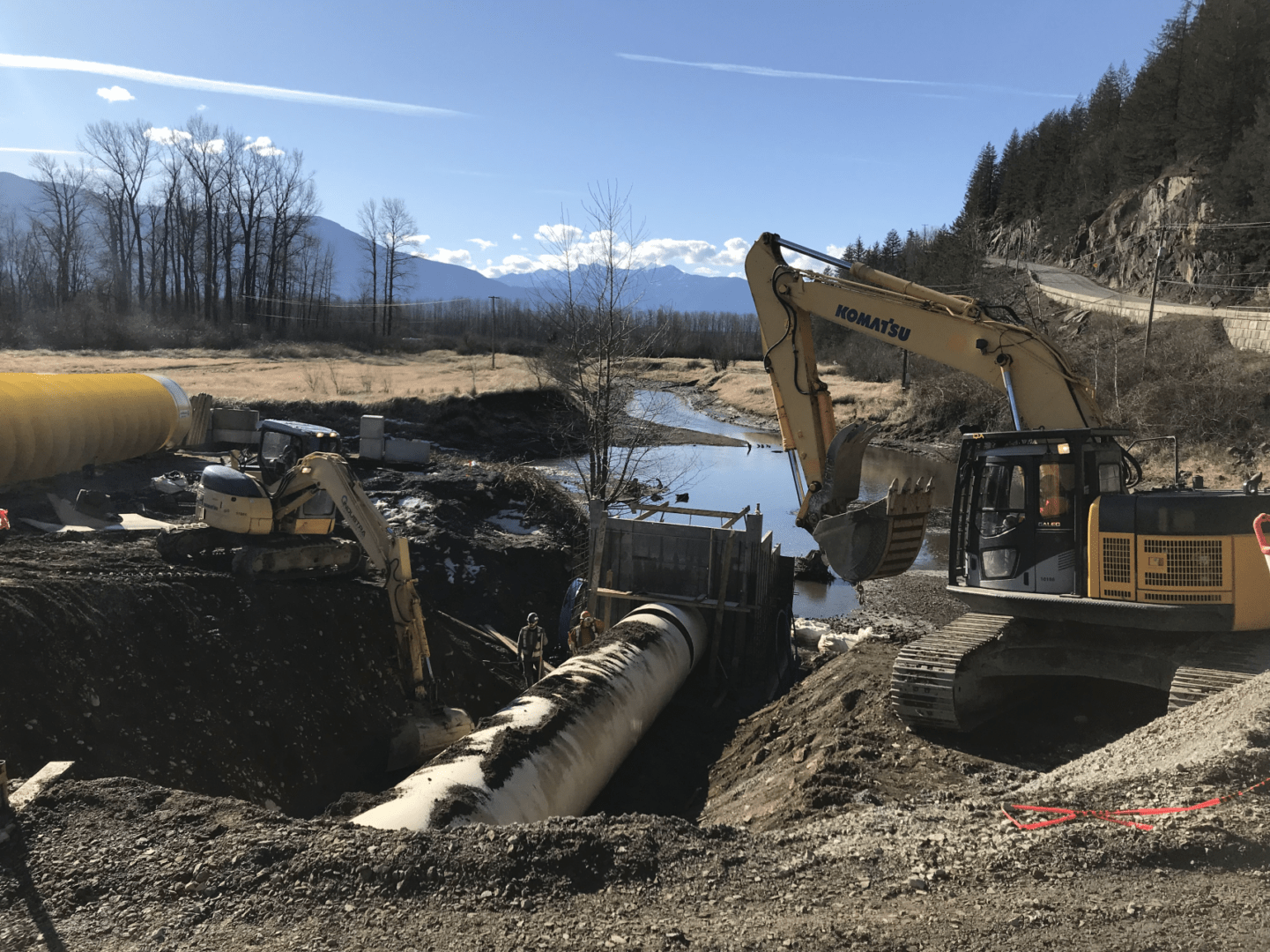

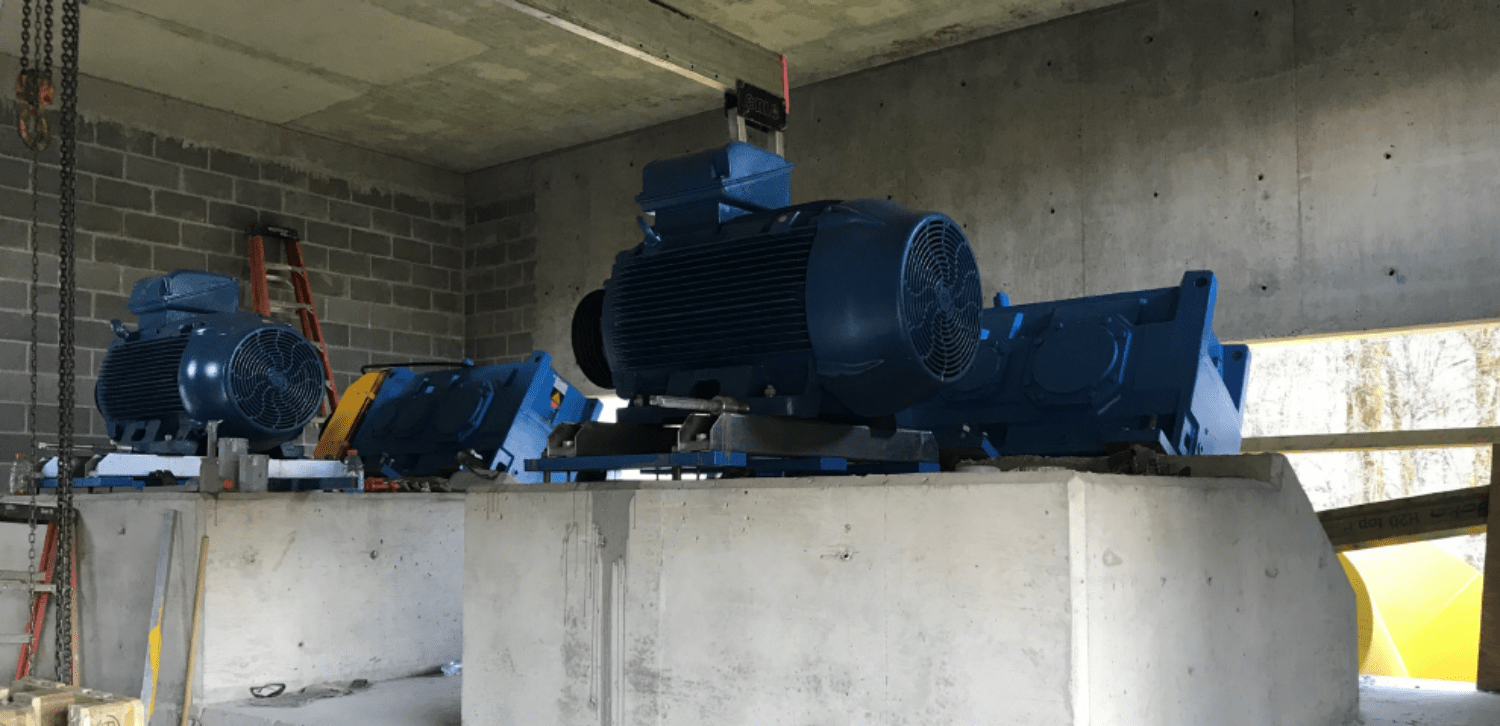

This project involved the new construction of a flood mitigation pump station in the Hammersley Dyke on the Fraser River. A massive concrete inlet structure housed two 9-foot (2.7 metre) diameter water turbines to draw freshet water from one side of the dyke and pump it directly into the Fraser River.

Challenges

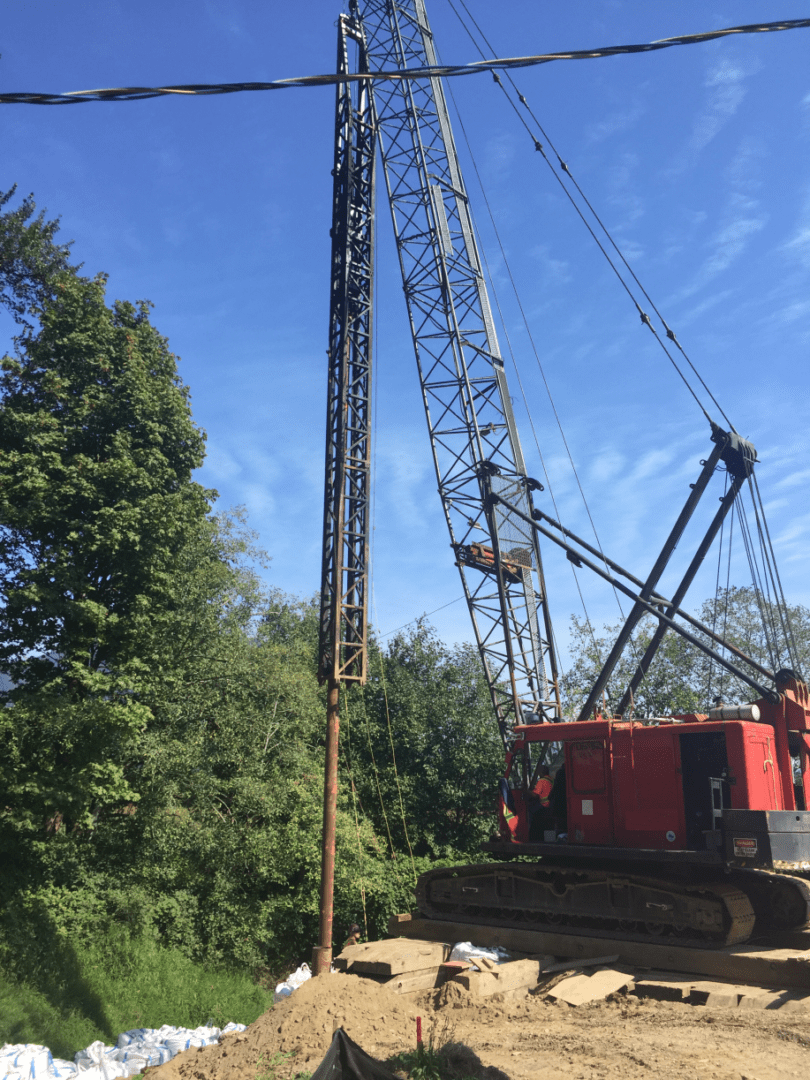

- River and stream cofferdams were a challenge to install and maintain during run-off periods.

- Dike water levels and permits were challenging with many environmental and utilities involved.

Additional Scope Items

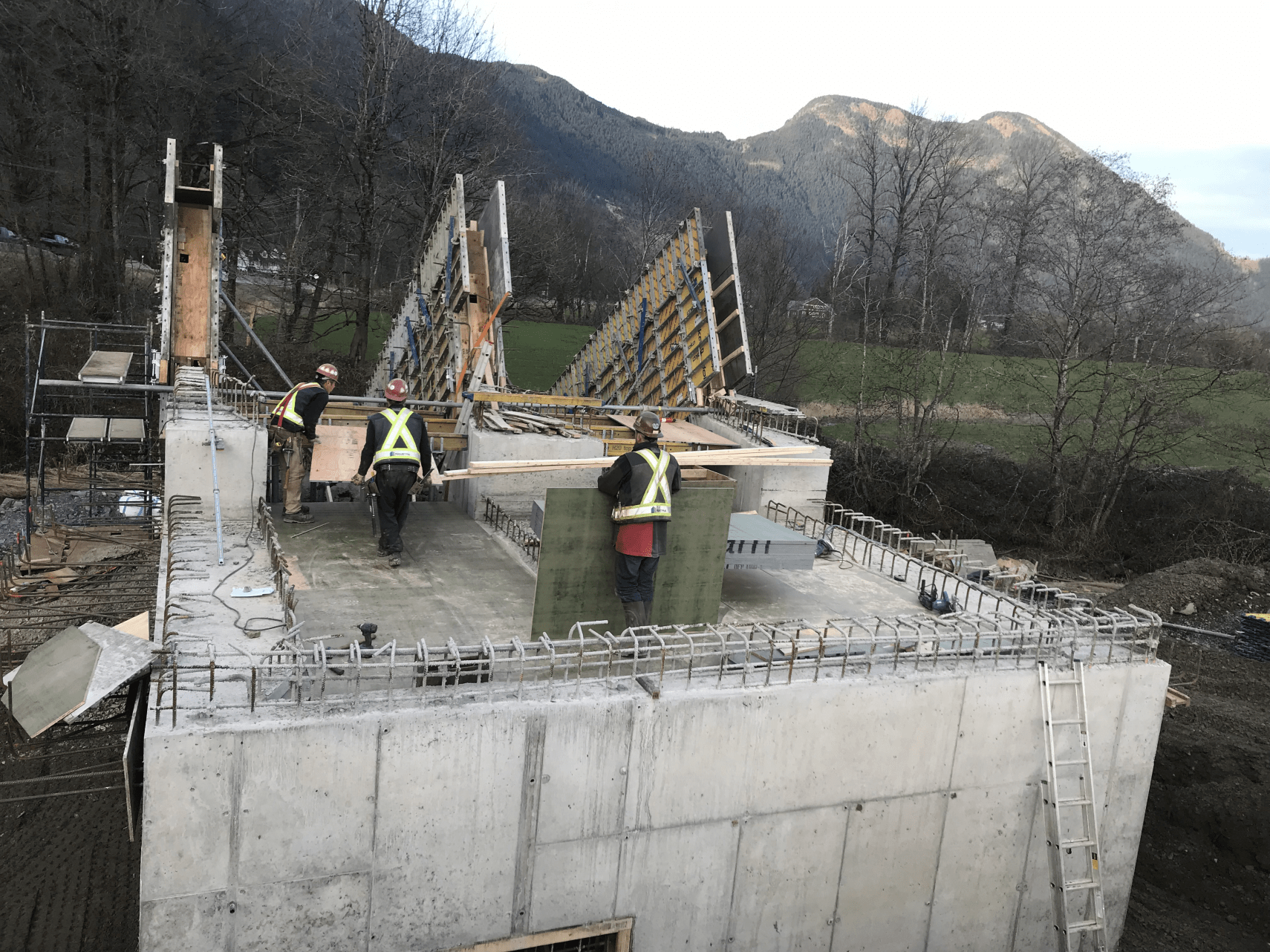

- Installation of reinforcing concrete channels for the new pumps.

- Pre-engineered foundation and outfall concrete structures.

- Heavy civil works including dike reconstruction.

- Large diameter epoxy-coated steel outfall piping.

- Concrete construction of the site inlet and outlet headwalls.

- Work involved environmentally-sensitive water management.

Hammersley Dyke Fish-Friendly Water Pump Station

Agassiz, British Columbia

This project involved the new construction of a flood mitigation pump station in the Hammersley Dyke on the Fraser River. A massive concrete inlet structure housed two 9-foot (2.7 metre) diameter water turbines to draw freshet water from one side of the dyke and pump it directly into the Fraser River.

Challenges

- River and stream cofferdams were a challenge to install and maintain during run-off periods.

- Dike water levels and permits were challenging with many environmental and utilities involved.

Additional Scope Items

- Installation of reinforcing concrete channels for the new pumps.

- Pre-engineered foundation and outfall concrete structures.

- Heavy civil works including dike reconstruction.

- Large diameter epoxy-coated steel outfall piping.

- Concrete construction of the site inlet and outlet headwalls.

- Work involved environmentally-sensitive water management.