Rossland Water Treatment Plant Improvements

Rossland, British Columbia

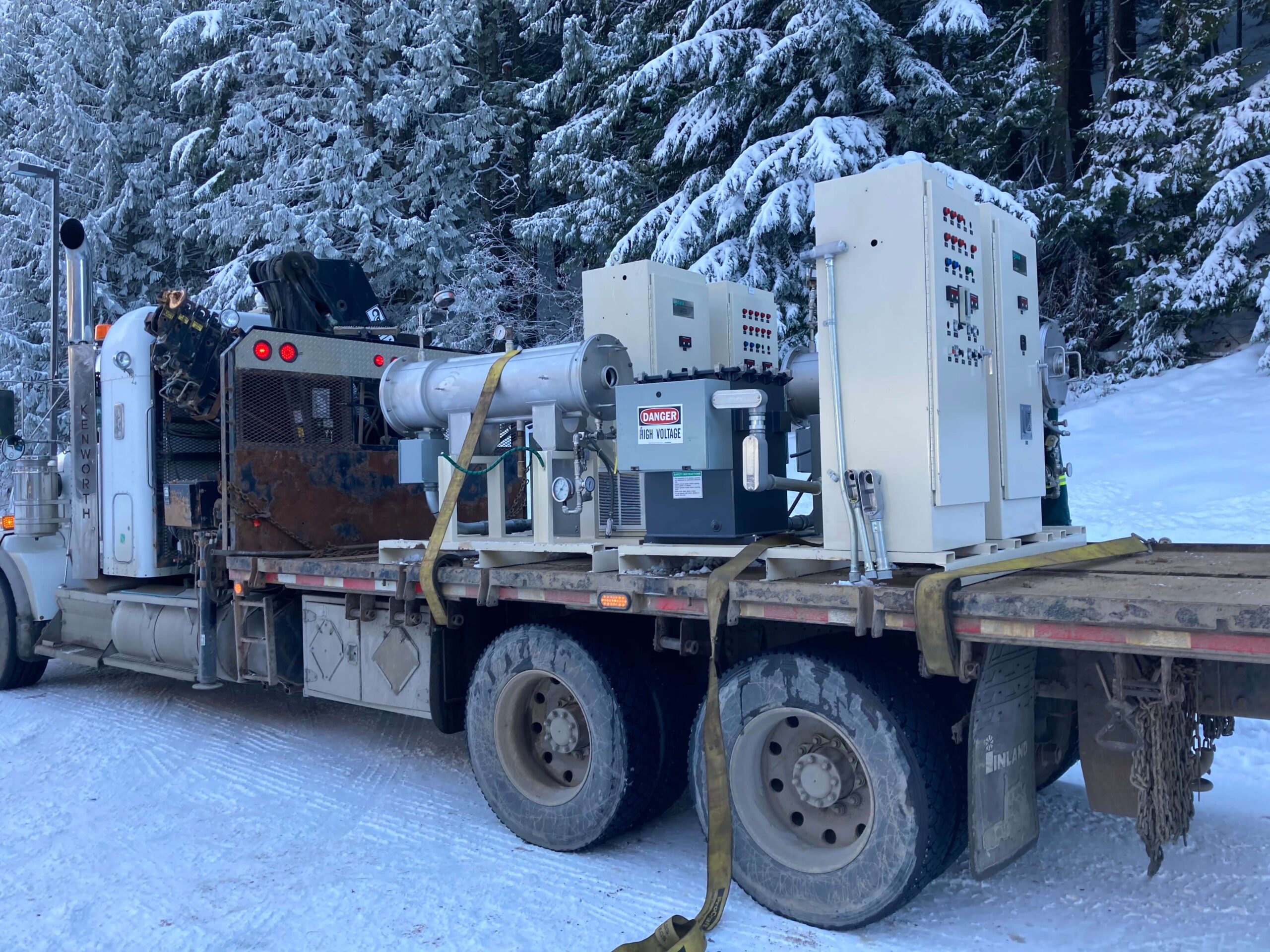

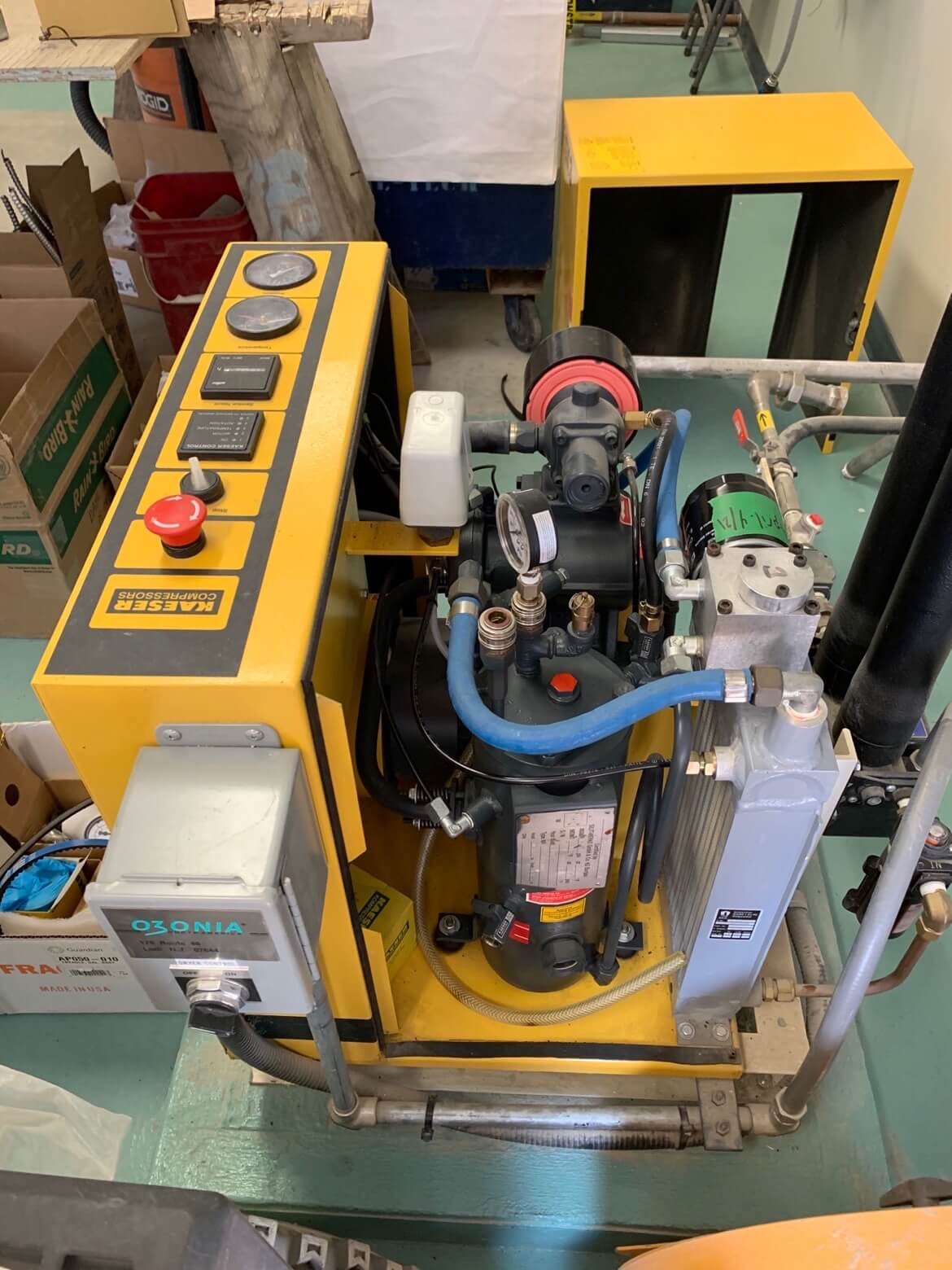

Various improvements to the existing Rossland Water Treatment plant including the supply and installation of the following: a soda ash dosing system, sodium-hypochlorite dosing equipment, fiberglass chemical tanks, sampling pumps, turbidity meters, pH meters, tankless water heaters, electrical equipment, standby generator. Start up and commissioning of each dosing system. SCADA upgrades to incorporate the new equipment. Decommissioning of the ozone, ammonia and chlorine gas systems.

Additional Scope Items

- Piping to all points including connections to water, drainage and vent piping.

- Provide natural gas piping to new water heaters.

- Coordinate installation of electrical and control requirements with the electrical contractor.

- Provide unit heater complete with supports, thermostats and controls.

- Provide start-up and commissioning of the heater.

- Supply and install diesel-fuel standby power generator and automatic transfer switch.

- Install motor control center components and assemblies.

- Install cable tray system.

- Power and control panel assemblies.

- Logic control systems (PLC) components and assemblies.

- Instrumentation.

- Supervisory control and data acquisition (SCADA) systems updates.

Rossland Water Treatment Plant Improvements

Rossland, British Columbia

Various improvements to the existing Rossland Water Treatment plant including the supply and installation of the following: a soda ash dosing system, sodium-hypochlorite dosing equipment, fiberglass chemical tanks, sampling pumps, turbidity meters, pH meters, tankless water heaters, electrical equipment, standby generator. Start up and commissioning of each dosing system. SCADA upgrades to incorporate the new equipment. Decommissioning of the ozone, ammonia and chlorine gas systems.

Additional Scope Items

- Piping to all points including connections to water, drainage and vent piping.

- Provide natural gas piping to new water heaters.

- Coordinate installation of electrical and control requirements with the electrical contractor.

- Provide unit heater complete with supports, thermostats and controls.

- Provide start-up and commissioning of the heater.

- Supply and install diesel-fuel standby power generator and automatic transfer switch.

- Install motor control center components and assemblies.

- Install cable tray system.

- Power and control panel assemblies.

- Logic control systems (PLC) components and assemblies.

- Instrumentation.

- Supervisory control and data acquisition (SCADA) systems updates.