The landscape of industrial processes is constantly evolving with new mechanical innovations. These advancements are designed to improve efficiency, reduce costs, and enhance the overall productivity of various operations. Understanding these innovations is crucial for those looking to stay ahead in the industry.

One of the key areas of focus is automation and robotics. These technologies take on repetitive tasks, allowing human workers to focus on more complex activities. This shift not only boosts productivity but also significantly reduces the risk of human error, improving overall quality and reliability. Alongside this, advanced pumping and piping technologies are revolutionizing the way fluids and materials are transported within industrial facilities.

Energy efficiency is another critical factor, as industries strive to minimize their environmental footprint while cutting down on operating costs. Innovative mechanical solutions that focus on reducing energy consumption and maximizing output are becoming increasingly important. Lastly, smart monitoring and predictive maintenance solutions are playing a pivotal role in maintaining optimal operational performance and preventing unexpected downtimes. By leveraging these innovations, industrial facilities can achieve higher efficiency, reliability, and sustainability.

Automation and Robotics in Process Mechanical Systems

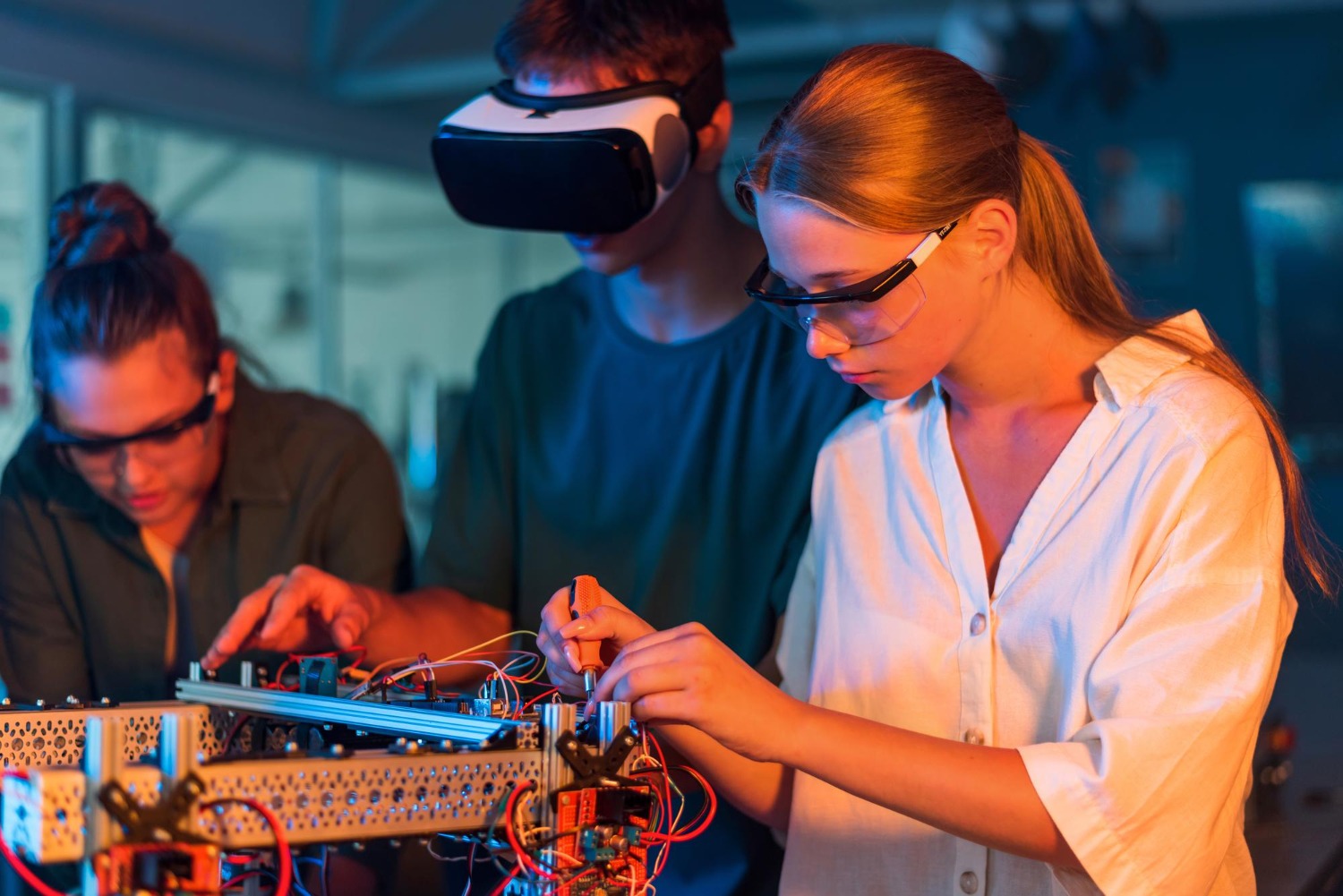

Automation and robotics have become game-changers in process mechanical systems, completely transforming how industrial tasks are performed. Automated systems can handle repetitive and strenuous tasks with high precision and speed, which significantly reduces the risk of human error. This not only improves overall productivity but also enhances the quality of the output. Robots equipped with advanced sensors and AI can adapt to various tasks, provide real-time data, and even predict issues before they become major problems.

In industrial settings, automation includes the use of conveyor belts, robotic arms, and automated vehicles. These machines are programmed to perform specific tasks such as assembling components, welding, and material handling. This reduces the reliance on manual labour and allows human workers to focus on more analytical and supervisory roles. Automation leads to fewer production delays, lower operational costs, and improved safety on the job site. By integrating these technologies, we can optimize workflow and maintain a consistent production rhythm.

Advanced Pumping and Piping Technologies

Advanced pumping and piping technologies are at the core of efficient material and fluid transport in industrial processes. Innovations in this area include the development of smart pumps that can adjust their operation based on real-time data. These pumps can automatically detect changes in pressure, flow rate, and temperature, adjusting performance to maintain optimal conditions. This not only ensures efficient operation but also extends the lifespan of the equipment by preventing wear and tear.

Piping technologies have also seen significant innovations. For example, the use of corrosion-resistant materials such as PVC and stainless steel can substantially increase the durability of piping systems. Advanced joining techniques like fusion welding and mechanical couplings make installation easier and more reliable. Modern piping systems also incorporate leak detection sensors that provide early warning signs of potential issues, enabling quick responses to prevent costly damage. These advancements in pumping and piping technologies streamline operations, reduce maintenance needs, and improve overall efficiency.

Energy-Efficient Mechanical Innovations

Energy efficiency is a critical concern in industrial process mechanical systems. Recent innovations aim to reduce energy consumption while maintaining high levels of productivity. For example, variable frequency drives (VFDs) are now commonly used to control motor speed and torque, adjusting energy use according to operational demands. This not only lowers electricity consumption but also extends the lifespan of the equipment by reducing mechanical stress.

Another notable innovation includes the use of energy recovery systems. These systems capture waste energy—such as heat from industrial processes—and convert it into usable power. This recycling process significantly cuts down on overall energy costs and reduces greenhouse gas emissions. Additionally, the adoption of high-efficiency motors and pumps contributes to lower energy requirements, further promoting sustainability. These advanced mechanical innovations help industrial facilities operate more sustainably while keeping operational costs down.

Smart Monitoring and Predictive Maintenance Solutions

Smart monitoring and predictive maintenance are revolutionizing industrial process mechanical systems by enhancing reliability and efficiency. Sensors and IoT devices are integrated into equipment to continuously monitor performance metrics such as temperature, vibration, and pressure. These smart-systems provide real-time data and analytics, allowing for immediate identification of any irregularities or potential issues.

Predictive maintenance takes this a step further by using machine learning algorithms to predict when equipment is likely to fail. This proactive approach means repairs and maintenance can be scheduled before a breakdown occurs, minimizing downtime and reducing maintenance costs. Implementing these solutions ensures that industrial operations run smoothly and efficiently, avoiding costly interruptions and extending the life of the equipment.

Conclusion

The rapid advancements in process mechanical innovations are reshaping the landscape of industrial operations. Automation and robotics, advanced pumping and piping technologies, energy-efficient solutions, and smart monitoring systems are all playing a pivotal role in enhancing efficiency, reducing costs, and maintaining sustainability. These innovations support the evolving needs of the industrial sector, allowing facilities to operate more effectively and responsibly.

At Industra Construction Corp., we are committed to integrating these cutting-edge technologies into your projects. Our expertise spans EPC design-build, civil construction, and other essential services to meet the unique requirements of your industrial ventures. Reach out to Industra Construction Corp. today to discover how our advanced process mechanical solutions can transform your operations and drive your success.