Efficient water systems are crucial for ensuring clean and safe water for communities and industries. Process mechanical engineering plays a vital role in keeping these systems operating smoothly. Understanding the ins and outs of these systems allows for optimal performance and reliability.

Process mechanical systems in water treatment involve a range of components and technologies. Each part must work together seamlessly to deliver water efficiently. Ensuring each element is in top condition requires careful planning and regular maintenance.

This article explores essential process mechanical tips to enhance the efficiency of water systems. By focusing on key areas of improvement, these tips help maintain water quality and system reliability. With the right strategies, we can ensure our water systems are effective and sustainable, meeting the needs of the future.

Understanding Process Mechanical Systems in Water Treatment

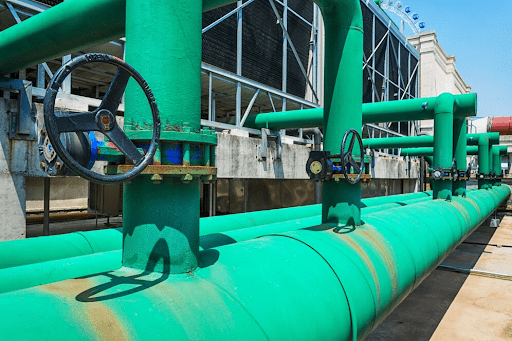

Process mechanical systems are essential in water treatment facilities. They include pumps, pipes, valves, and other equipment that move and treat water. These components must work together to ensure the system operates correctly and meets necessary standards. Understanding how each part fits and functions is key to managing and optimizing the process.

Water treatment involves several steps, starting with the collection of raw water and ending with the distribution of treated water. Each of these steps requires specific mechanical processes to filter out impurities and ensure water purity and safety. Process mechanical systems are responsible for maintaining the flow and pressure needed for these tasks to happen efficiently.

Key components of these systems include:

– Pumps: Essential for moving water through the various treatment stages. They ensure the correct pressure and flow rate.

– Valves: Control water flow and pressure. They ensure the system operates smoothly and can handle varying demands.

– Filters: Remove solids and impurities, making them an integral part of delivering safe water.

By keeping these components in mind, operators can ensure their water systems run smoothly. A clear understanding helps in spotting issues early and fixing them before they become major problems.

Key Components for Optimal Performance

For water systems to perform well, each mechanical component must be in top shape. Ensuring optimal performance involves not just having good equipment but also knowing how it works and how to maintain it. Proper maintenance and regular inspections prevent breakdowns and ensure a steady supply of clean water.

Components crucial for optimal performance include:

– Efficient Pumps: Select pumps that match the system’s needs. Variable-speed pumps offer flexibility and can adapt to changing water demands, saving energy.

– High-Quality Pipes: Choose pipes that resist corrosion and leakage to prevent costly repairs and water loss. Regular inspection and maintenance can extend their life.

– Robust Control Systems: Automated control systems monitor the operation and help quickly identify and address issues, ensuring seamless performance.

Additionally, the system should integrate technology that supports performance. Smart sensors and real-time monitoring tools provide valuable data, allowing for adjustments that enhance efficiency. Training staff in handling these components is also vital, ensuring they can manage and troubleshoot effectively.

Adopting best practices and focusing on component quality helps create a water system that consistently delivers. Understanding the components’ roles and maintaining them can lead to significant cost savings and environmental benefits, while providing reliable water service to the community.

Maintenance Tips for Prolonged Efficiency

Keeping water systems efficient over time involves regular maintenance of process mechanical components. Consistent upkeep reduces the risk of unexpected breakdowns and extends the lifespan of the equipment. By focusing on preventative measures, water systems can maintain high performance and reliability.

Start with a detailed maintenance schedule that includes:

– Regular Inspections: Check pumps, valves, and pipes for signs of wear or leaks. Early detection of issues can save time and money.

– Scheduled Cleanings: Remove buildup in filters and other components. Cleaning ensures that water flows smoothly and remains uncontaminated.

– Routine Testing: Perform tests to ensure components function as intended, adjusting settings as necessary for optimal performance.

Training staff to perform these tasks ensures that maintenance is thorough and timely. Having a well-documented process also helps, as it makes tracking maintenance easy and provides data that guides future decisions.

Furthermore, establish a protocol for swiftly addressing repairs. Quick responses to small issues can prevent them from becoming major problems. Investing in quality spare parts and tools can also facilitate faster repairs and minimize downtime. With these maintenance practices, water systems can remain efficient and reliable, meeting the needs of growing communities.

Leveraging Technology for Smarter Water Systems

Technology is transforming water systems by making them smarter and more efficient. Implementing the right technology can enhance monitoring, data collection, and system operations. This leads to better decision-making and conservation efforts that save resources.

Smart water systems benefit from:

– Real-Time Monitoring: Use sensors to track flow rates, pressure, and quality, providing instant alerts when problems arise.

– Automated Controls: Adjust the system automatically to meet demand, optimizing energy use and performance.

– Data Analytics: Analyse collected data to identify patterns and predict maintenance needs, helping prevent issues before they occur.

By using technology wisely, water systems can become proactive rather than reactive. This approach allows facilities to maintain a high standard of service while reducing operational costs.

Training teams to interpret and use this technology ensures everyone benefits fully. By embracing these innovations, operators create water systems that are resilient, adaptable, and ready for future challenges.

Conclusion

Ensuring water systems operate efficiently requires a blend of solid mechanical foundations, diligent maintenance, and cutting-edge technology. Process mechanical systems form the backbone of these operations, dictating how well facilities manage and treat water resources. By understanding the intricacies of these systems, facilities can optimise their performance and ensure long-lasting functionality.

Industra Construction Corp. brings expert insight into building and maintaining efficient water systems. Our comprehensive approach combines the latest technologies and proven methods to deliver water solutions tailored to community needs. By partnering with us, you can ensure your water systems remain efficient and reliable, meeting both immediate and future demands with precision and care. Reach out today to discover how our water treatment construction services can support your water management goals.