Anacla Community Wastewater Treatment System

Bamfield, British Columbia (Vancouver Island)

This new wastewater treatment plant (WWTP) for the Huu-Ay-Aht First Nations includes three new buildings, a lift station, HDPE forcemain construction, a marine outfall, and installation of process mechanical and electrical for the new WWTP. Major stakeholders included the Huu-Ay-Aht First Nations, Bamfield Marine Sciences Centre and Indigenous Services Canada.

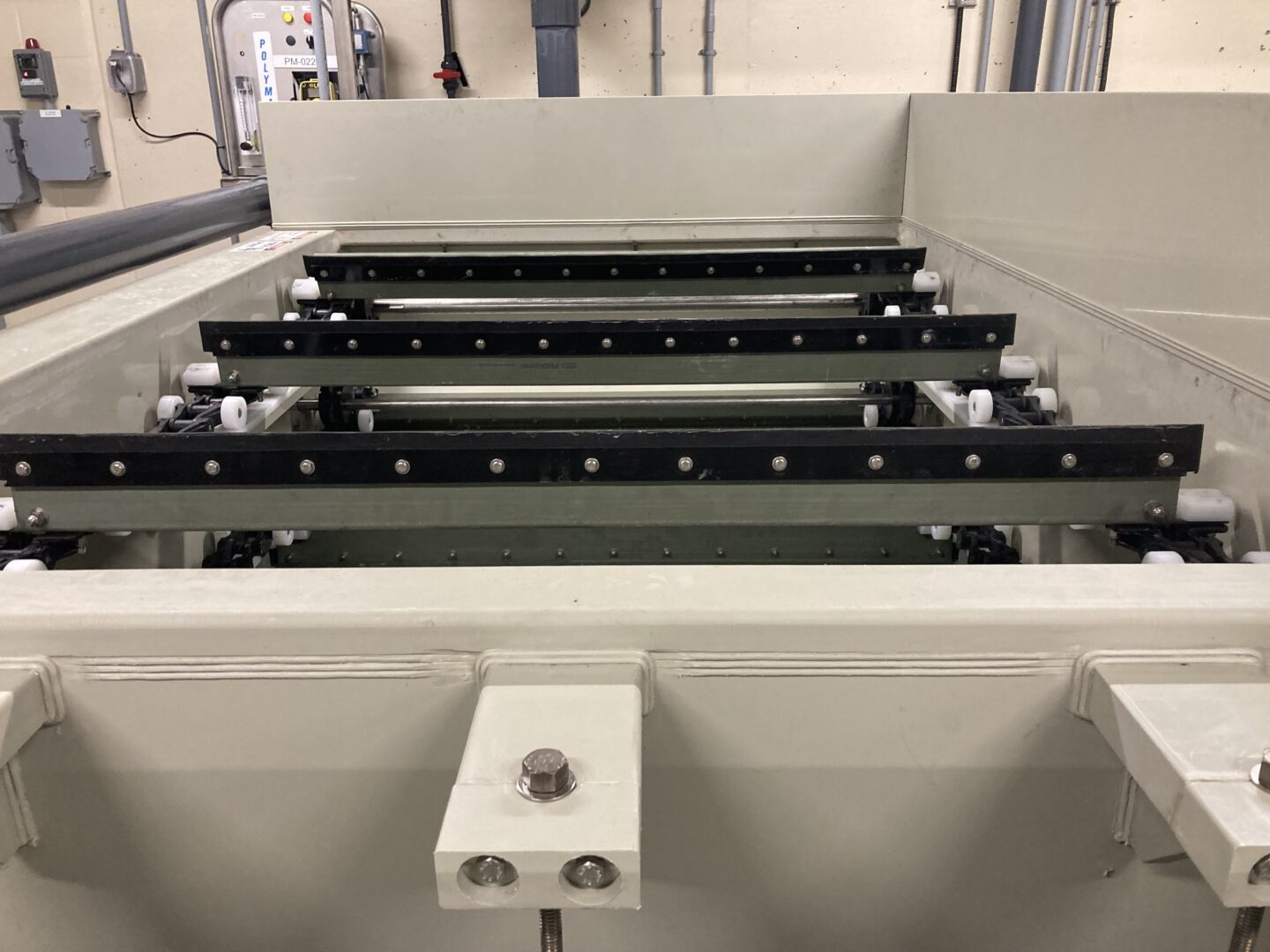

The new plant, which will accommodate up to 1,100 people and allows for expansion, was designed by McElhanney and uses a moving bed biofilm reactor system (MBBR) to treat the wastewater.

Positive Aspects

- By self-performing much of the work, this gave us the ability to increase or decrease manpower as required to suit the schedule.

- Worked hand-in-hand with the Huu-Ay-Aht First Nations for sourcing local materials including aggregate and concrete supply.

- Maximized the use of local resources which lead to economic benefits for the local community.

Additional Scope Items

WWTP:

- Site works (e.g., clearing, excavation, rock removal, plumbing, site grading, fencing, landscaping).

- Structures (e.g., screen/chemical room, tanks, UV/DAF building, service building).

- Process/mechanical (major and ancillary) equipment.

- WWTP electrical, instrumentation, and process control equipment.

Wastewater Conveyance System:

- Lift station including kiosk, wet well, duplex pumps, flow meter chamber, backup generator, and site works.

- HFN forcemain including approximately 1000m of forcemain c/w associated works (e.g., dosing chamber, air valve assemblies, flushout assemblies, valves, fittings, connections) to convey the wastewater to the WWTP Site and treated effluent to the outfall.

- Bamfield Marine Science Centre forcemain including approximately 850m of forcemain c/w associated works (e.g., air valve assemblies, flushout assemblies, valves, fittings, connections) to convey the wastewater from BMSC to the WWTP site.

Outfall Upgrades:

- Marine outfall extension including approximately 380m of 200mm HDPE pipe, connection to existing outfall, concrete pipe weights, and diffuser of forcemain c/w associated works (air valve assemblies, flushout assemblies, valves, fittings, connections) to convey the wastewater from BMSC to the WWTP site.

Anacla Community Wastewater Treatment System

Bamfield, British Columbia (Vancouver Island)

This new wastewater treatment plant (WWTP) for the Huu-Ay-Aht First Nations includes three new buildings, a lift station, HDPE forcemain construction, a marine outfall, and installation of process mechanical and electrical for the new WWTP. Major stakeholders included the Huu-Ay-Aht First Nations, Bamfield Marine Sciences Centre and Indigenous Services Canada.

The new plant, which will accommodate up to 1,100 people and allows for expansion, was designed by McElhanney and uses a moving bed biofilm reactor system (MBBR) to treat the wastewater.

Positive Aspects

- By self-performing much of the work, this gave us the ability to increase or decrease manpower as required to suit the schedule.

- Worked hand-in-hand with the Huu-Ay-Aht First Nations for sourcing local materials including aggregate and concrete supply.

- Maximized the use of local resources which lead to economic benefits for the local community.

Additional Scope Items

WWTP:

- Site works (e.g., clearing, excavation, rock removal, plumbing, site grading, fencing, landscaping).

- Structures (e.g., screen/chemical room, tanks, UV/DAF building, service building).

- Process/mechanical (major and ancillary) equipment.

- WWTP electrical, instrumentation, and process control equipment.

Wastewater Conveyance System:

- Lift station including kiosk, wet well, duplex pumps, flow meter chamber, backup generator, and site works.

- HFN forcemain including approximately 1000m of forcemain c/w associated works (e.g., dosing chamber, air valve assemblies, flushout assemblies, valves, fittings, connections) to convey the wastewater to the WWTP Site and treated effluent to the outfall.

- Bamfield Marine Science Centre forcemain including approximately 850m of forcemain c/w associated works (e.g., air valve assemblies, flushout assemblies, valves, fittings, connections) to convey the wastewater from BMSC to the WWTP site.

Outfall Upgrades:

- Marine outfall extension including approximately 380m of 200mm HDPE pipe, connection to existing outfall, concrete pipe weights, and diffuser of forcemain c/w associated works (air valve assemblies, flushout assemblies, valves, fittings, connections) to convey the wastewater from BMSC to the WWTP site.